FEA (Finite Element Analysis)

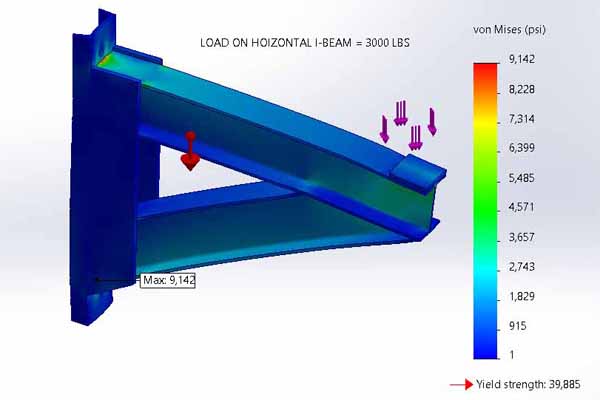

FEA is used to ensure that structural and mechanical products will support their design loads. Classical stress

analysis (CSA) is used on common structural components when mechanical properties are known. FEA is used on

uncommon shapes whose mechanical properties are not known, or for structures that are too complex for CSA.

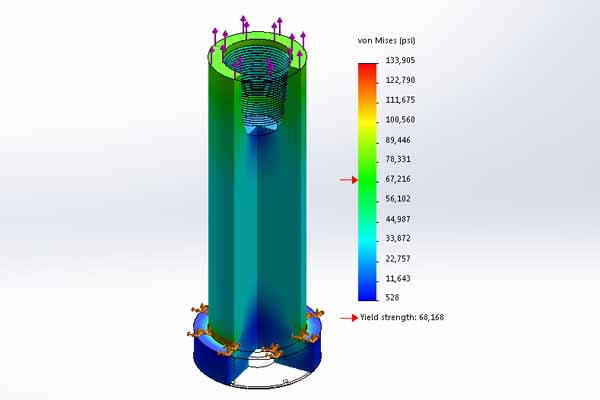

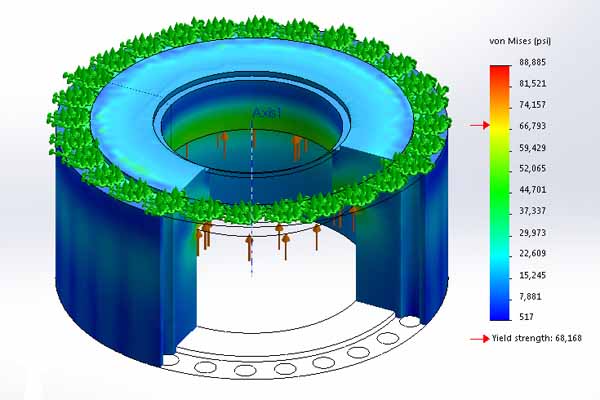

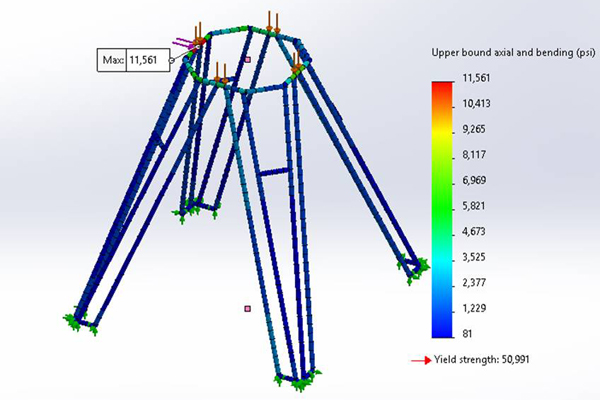

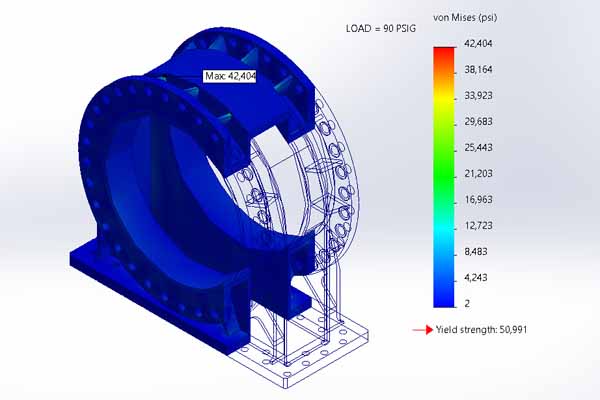

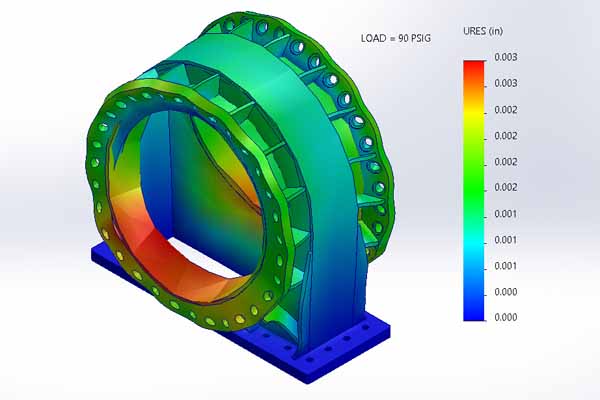

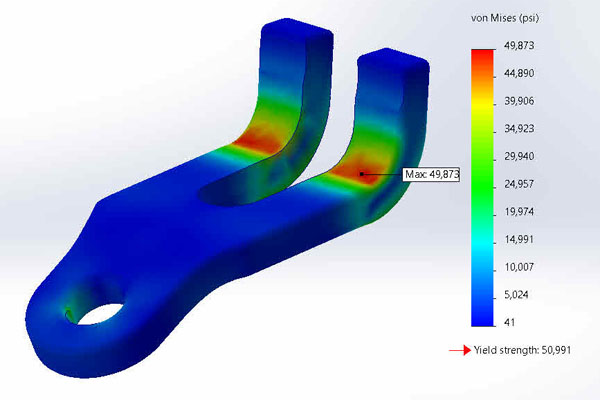

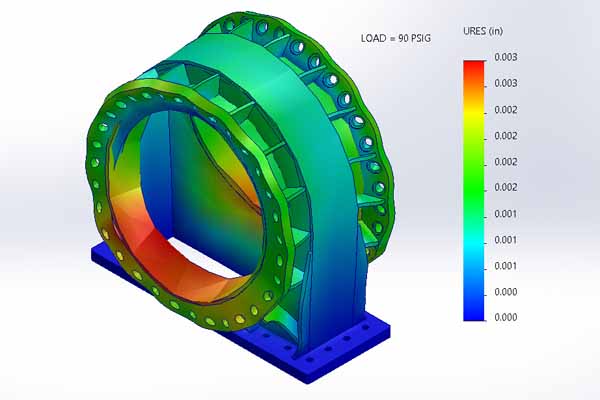

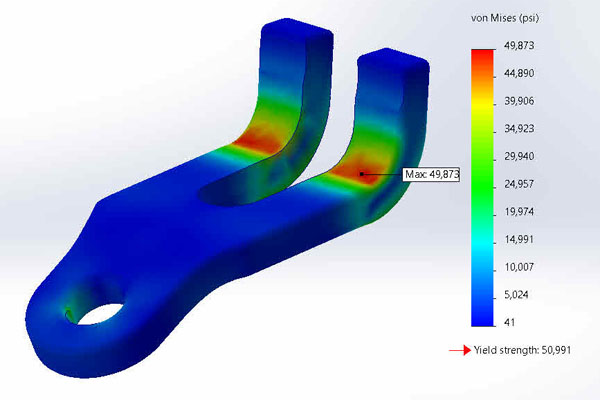

When running a FEA analysis, a SolidWorks model of the product is constructed. This model is imported into

SolidWorks Simulation, where material properties, boundary conditions and loads are applied. After the FEA analysis

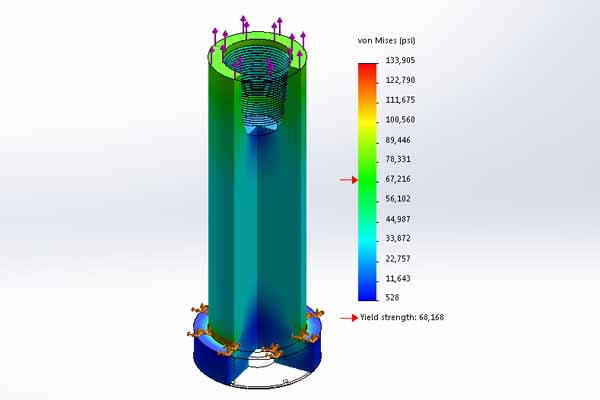

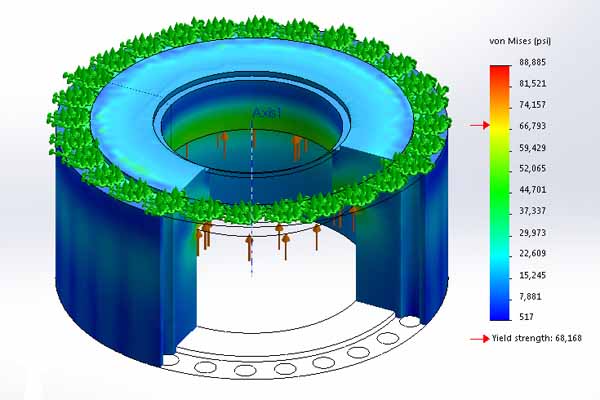

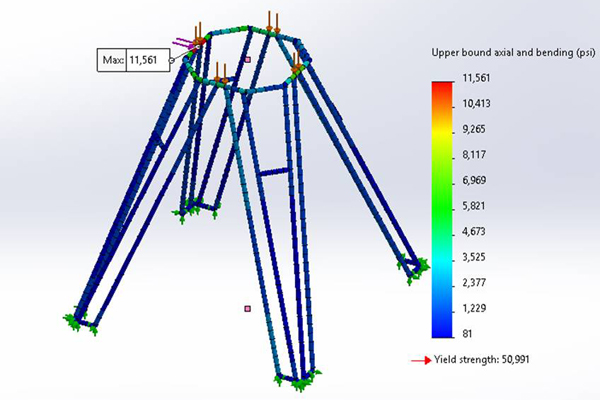

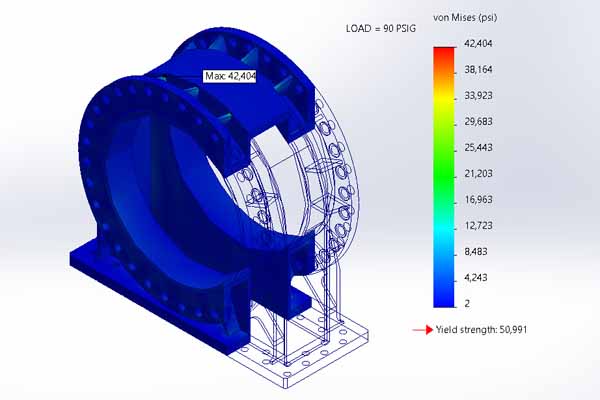

is run, stress and deflection plots, like the examples shown below, are generated. These stress values in these

plots are compared to the product's material yield strength to ensure he product's structural integrity.

FEA Analyzed Models

The slide show below shows the FEA results of mechanical and structural components when subjected to their

respective design loads.

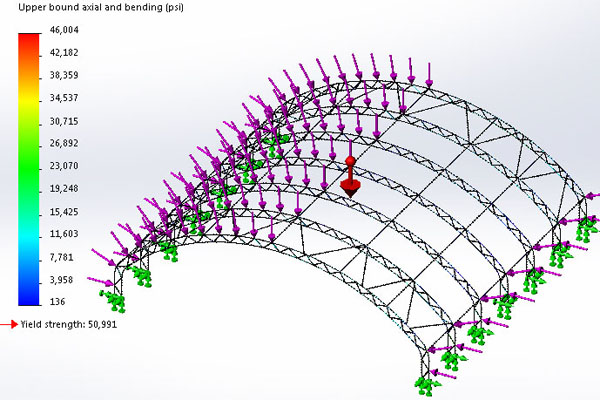

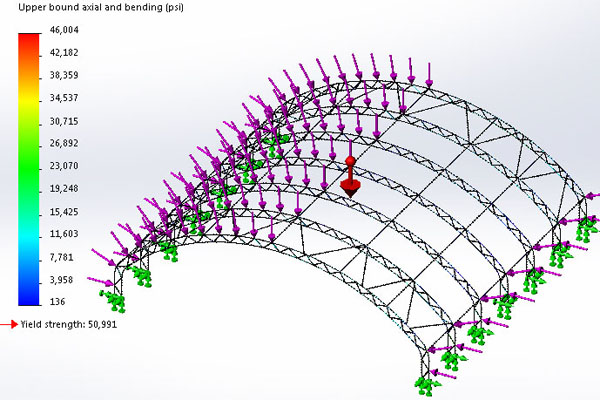

Tent Support Structure Stress, Load = 100 mph (161km/hr) Wind.

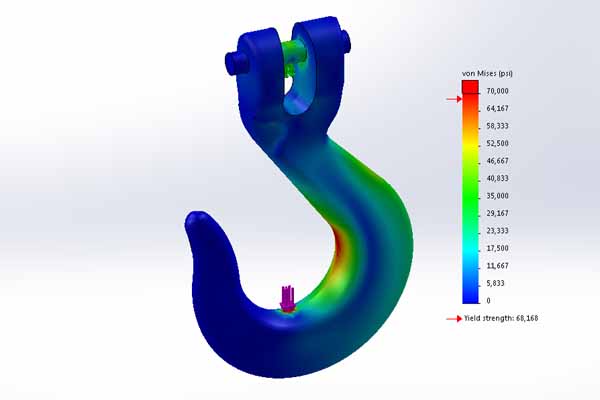

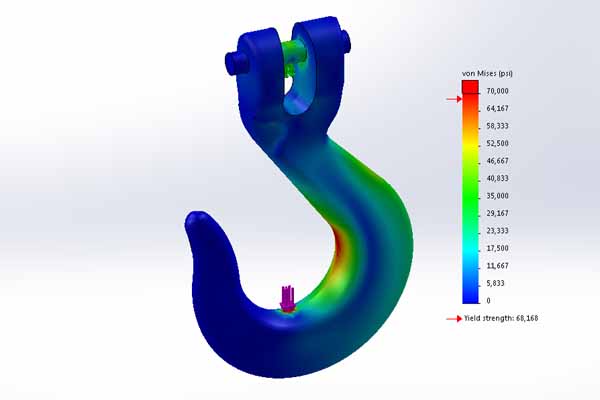

Chain Hook Stress, Load = 5 kips (22.2 kN).

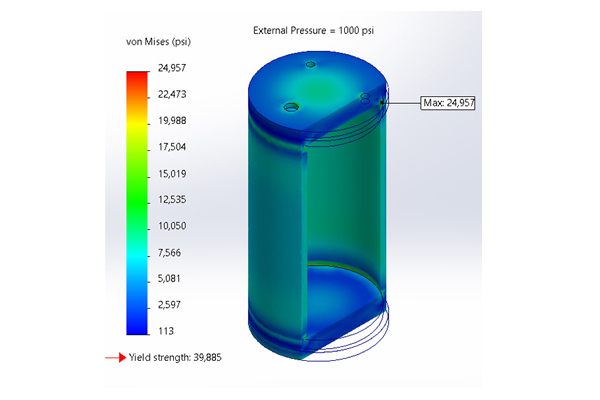

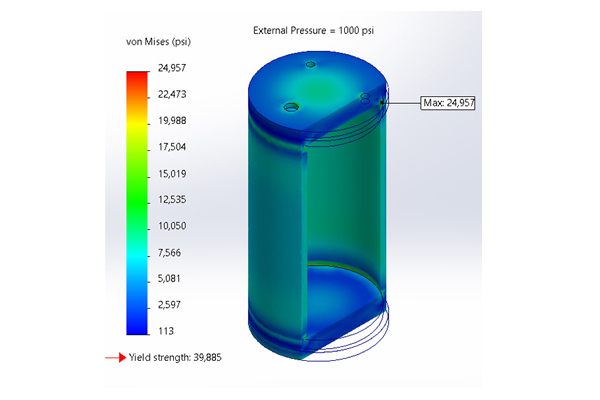

IPV Stress, External Pressure = 1000 psi (6.9 MPa).

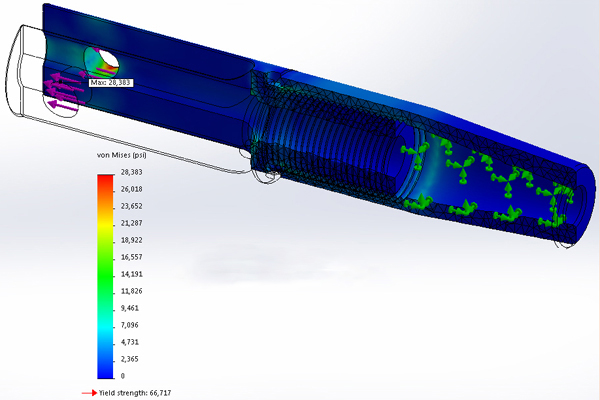

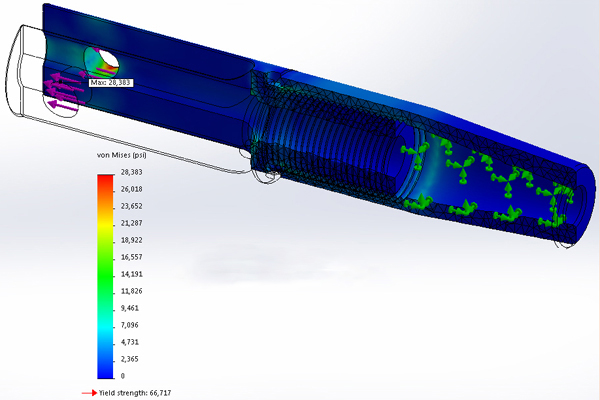

Armored Cable Termination Stress, Load = 10 kips (44.5 kN).

Boat Lift Piling Support Stress, Load = 3 kips (13.3 kN).

BLAT Drive Pipe Stress, Load = 2000 kips (8.9 MN).

BLAT Top Breech Lock Stress, Load = 2000 kips (8.9 MN) .

Storage Tank Weldment Stress, Load = 24 kips (106.8 kN) .

Slurry Gate Valve Stress, Load = 90 psi (620.5 kPa) .

Slurry Gate Valve Deflection, Load = 90 psi (620.5 kPa) .

Anchor Chain Hook Stress, Load = 12 kips (53.37 kN) .

What FEA Can Do For You

FEA is used to calculate stress

and deflection in machine parts,

assemblies, & weldments

subjected to design loads

whose complex geometries

don't allow the use of CSA.

SolidWorks Simulation uses FEA

to improve a product's reliability

by predicting its behavior when

subjected to it's design loads.

Classic Beam Stress Analysis Example

Click on the STRESS FAILURE

CRITERIA ICON below to see a

MapleSoft I-Beam stress

analysis that calculates stress

& deflection in two (2) I-Beams

when they are subjected to their maximum

allowable load.

Connect With Us