.

3D Printing

.

What is 3D Printing:

.

3D printing (Additive Manufacturing) utilizes a 3D cad model of a part to produce the part that you need. This 3D cad model is then saved in a format that can be recognized by a 3D printer. The 3D printer creates the part one layer at a time from from the printer material. The layers are fused together to form a part that is identical in shape to the 3D cad model. Some of the 3D printing technologies available are FDM (Fused Deposition Modeling), Polyjet, Stereolithography, Laser Sintering, and Metal Powder Bed Fusion. 3D Printing is ideal if you only need a small quantity of parts that doesn't justify tooling and machine set up expenses.

.

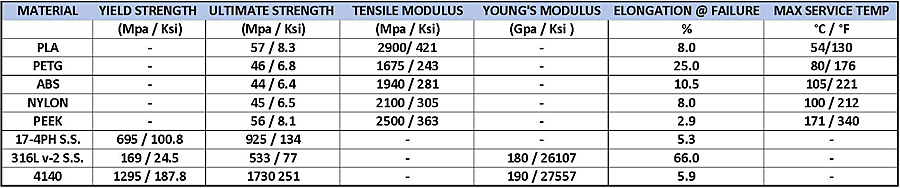

Typical Properties of 3D Printed Materials:

.

.

.

How We Can Create 3D Printed Parts for You:

.

We need a 2D drawing or sketch of the your part, from which we will create a 3D CAD model. This CAD model can be sent directly to you in 3D printer format (.STL), or to a company that specializes in 3D Printing. Because 3D printing requires no tooling or set up, the part will be created in less time with less expense than would be incurred by machining your part.

.

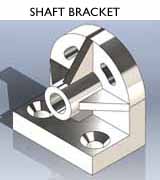

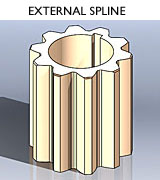

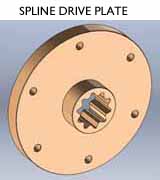

Examples of Parts That Can Be 3D Printed:

.

Connect With Us